We have become nationally recognized as an industry leader – focusing on Quality, Technology and Innovation, investing in the future of our customers, our company and our employees.

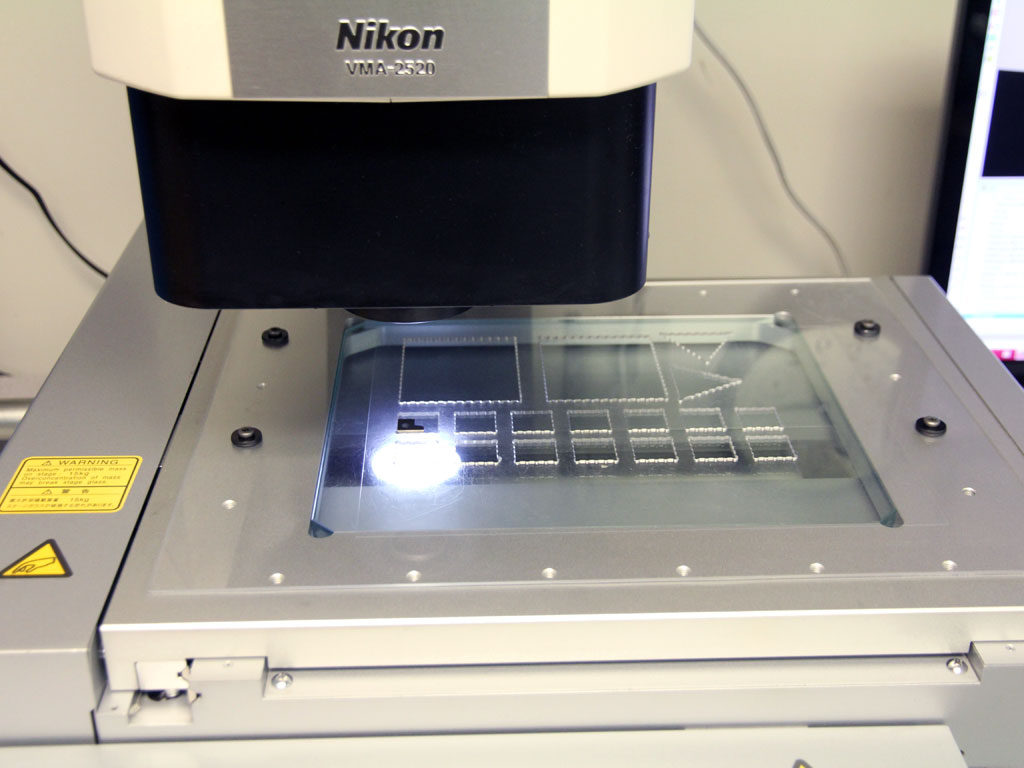

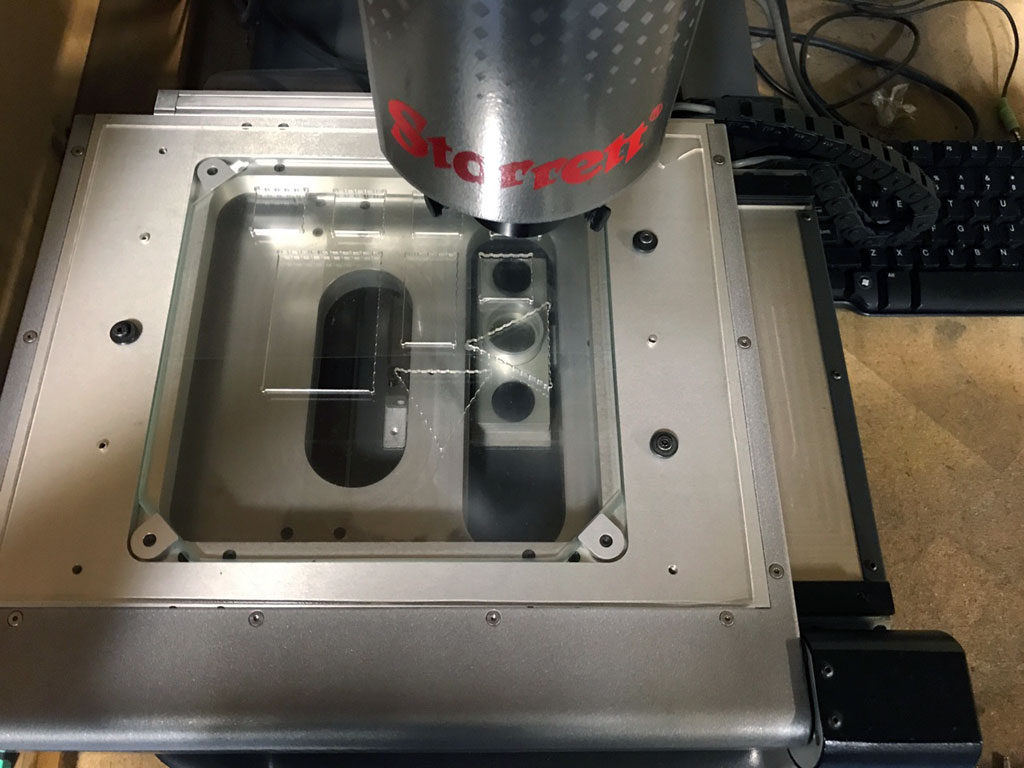

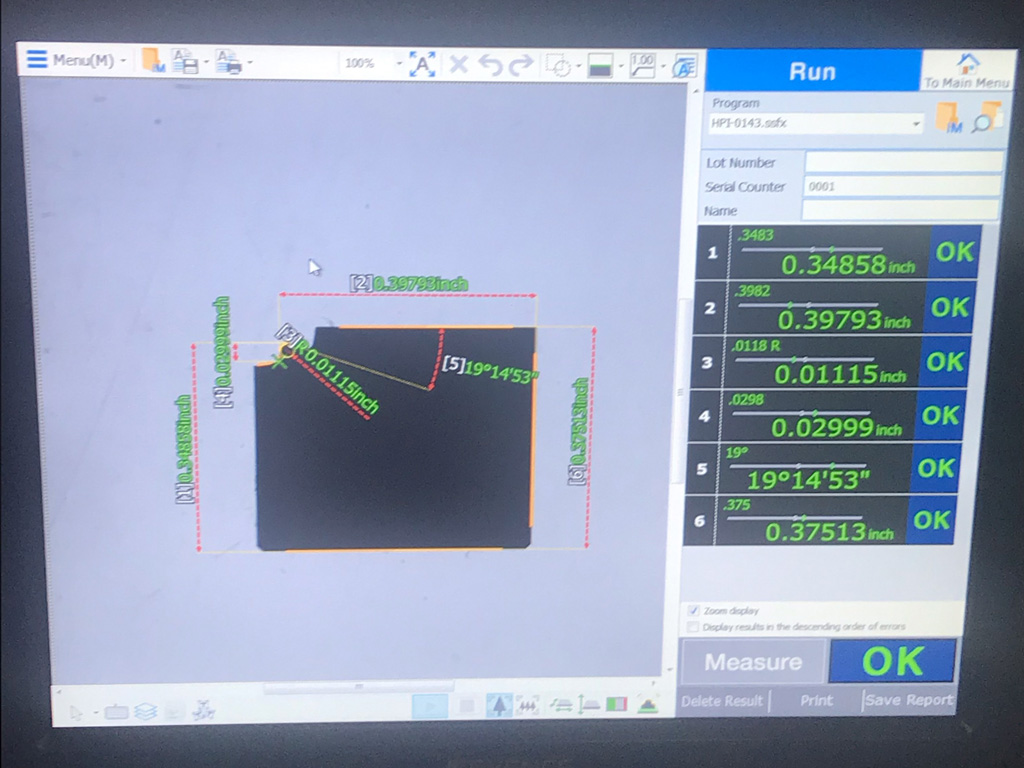

We’ve been providing outstanding quality for over 44 years in the fabrication of the most difficult and demanding blueprint special cutting tools. We have developed a “lean” manufacturing processing system with the latest in CNC grinding technologies. Combined with our ISO 9001:2008 Certified Quality Assurance Program, we offer reliability, innovation and personal service for any application.